Yarn Storage Feeder

-

Jacquard Yarn storage Feeder Jacquard Circular Knit Machine spares

The three phase 42V yarn storage feeder is designed for Jacquard circular knit machine. It is with power 50W. The max afford revolution speed will be 1500r/min. It is equipped with micro-processors,can intelligently judge yarn tension that being overstretched thus avoiding unnecessary yarn break. Jingzhun Machine Jacquard yarn feeder highly improve production efficiency. Its lower power consumption and less heat, greatly reduce the power consumption of the knitting machine, at the same time highly improve the weaving efficiency. We also provide a wide range of yarn feeder for the circular knit machine like JC-626 style , JC-627 style , JC-524 Wal Lycra yarn feeder and others. Also, we are capable of modifying the yarn feeders to suit your particular needs. We ensure the highest quality of products with our excellent quality control and testing system.We have a highly experienced and skilled technicians team who constantly develop and extend our product ranges. Our global marketing and distribution system enable us to deliver the products faster worldwide. We come to you with confidence and quality.

-

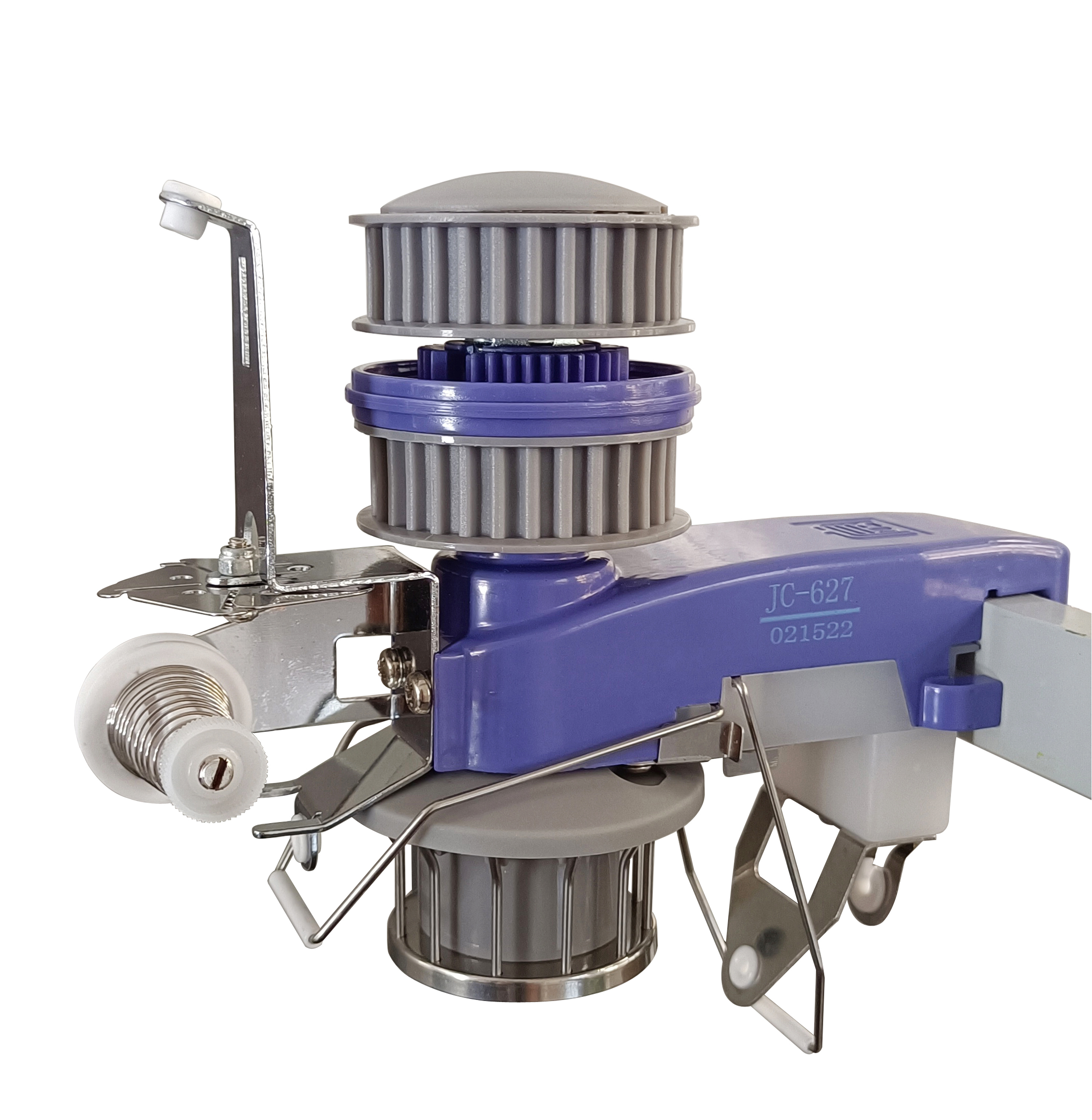

Jc-627 Yarn Storage Feeder For Circular Knit Machine

The JC-627 yarn storage feeder with steel wheel being treated by special technology to provide excellent wear resistance and corrosion resistance. The customized 10mm intermediate shaft to ensure more stable yarn feeding. With the dedicated bearings, the yarn feeding become more smooth and less noise, it can bear high temperature and high speed, longer life.

-

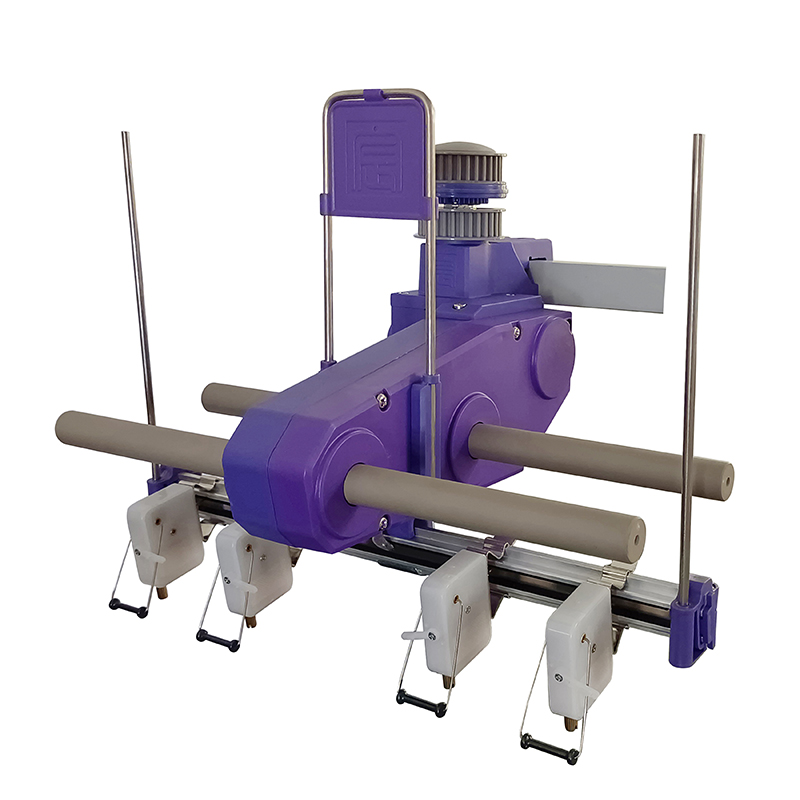

Jc-626 Yarn Storage Feeder For Circular Knit Machine

The JC-626 yarn storage feeder used on circular knit machine. The key point is that the yarn storage wheel adopts new technology, “micro-arc surface treatment” which is wear-resistant and corrosion-resistant. We offer 5 years free replacement except artificial case. We also have customized 10mm intermediate shaft, it is more stable when yarn feeding. With the dedicated bearings, the yarn feeding become more smooth and less noise, it can bear high temperature and high speed, longer life.

-

Wal Lycra Feeder Jc-tk524 For Circular Knit Machine

The Wal Lycra feeder JC-TK524 is with universal elastane roller which is designed for the positive feeding of plain elastane yarn to large-diameter circular knitting machines.It is developed to process plain elastane at even lower yarn tensions. The feeder yarn breaking stop adopts mechanical lever structure and can be adjusted according to the tension of spandex. After yarn breaking, it blocks the optical path and violates the yarn breaking stop signal.The Wal Lycra feeder is produced with the best raw materials. The roller with solid aluminum alloy and micro arc oxidation surface, more wear-resistant, anti-fouling and anti-corrosion. We constantly improve the production programme in order to ensure a better quality and super service. We have been focusing on the production process to always be care of the goods quality. We have got high praise by partner. If you have any require need, feel free to send us, we will back to you as soon as possible. Looking forward to hearing your call and emails.

-

circular knit machine positive yarn storage feeder JC-626

The JC-626 positive yarn Feeder is of voltage AC 12/24V, revolution Speed 2000r/min. Compared to the yarn feeder in the market, the JC-626 have those Points of process improvement.

Firstly: The circuit base contacts copper sheet with silver-plated to prevent oxidation;

Secondly: The yarn feeder use 10mm intermediate shaft which can ensure a more stable yarn feeding;

Thirdly: all the bearings are imported and customized.

Best of all that the yarn storage device is equipped with front and rear separated limit pieces, thus user can quickly close the road, reducing the machine workload and adjusting personnel in the case of special cloth use.